VIVA MFC

History of Wastewater Technology

The First Water Technology

The Mesopotamians invented Toilets and Sewers (the purpose: moving wastewater away from where people live)

Aeration Wastewater for Treatment

Edward Ardern and W.T. Locketts discovered the activated sludge process. (Microbes break down waste, and they need to breathe)

Clean Water Act (US)

Aeration is widely adopted in the US (for municipal waste and industrial plants). A game changer for human and ecological health.

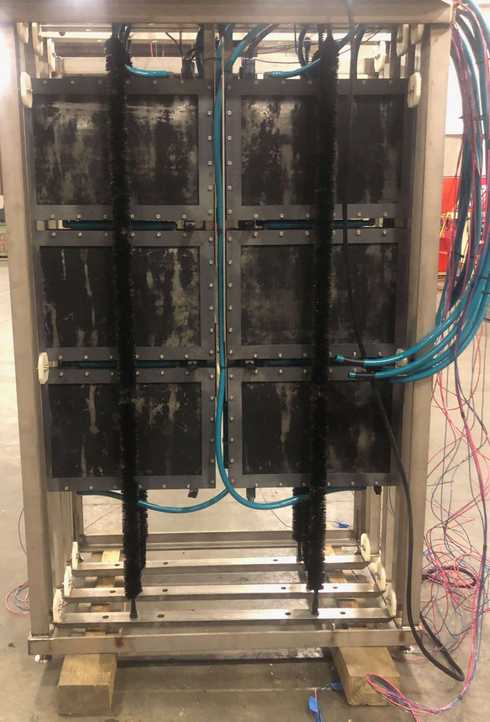

VIVA™ MFC

VIVA MFC is a fundamental shift in wastewater, providing the most sustainable and cost-effective wastewater treatment system for industrial and municipal waste streams. VIVA reducing energy use in treatment by 85-90% and providing real-time performance data, to minimize the carbon footprint and provide better treatment

Massive Energy Use

Current Wastewater Treatment is extremely energy-intensive. On average, Aeration takes 1600 kWh to treat one million gallons of municipal waste. Industrial waste can be up to 35 times more energy-intensive. With over 34 Billion Gallons of Municipal US waste every day, it’s no surprise that aeration, which uses 45-80% of a plant’s power use, and 15-20%: of plant operating expense, is responsible for 4% of US electricity consumption. Industrial Waste (food & beverage, oil & gas, textiles, paper & pulp, and other industrial sectors) is even more energy-intensive than municipal waste.

The Aeration Problem

- Aeration typically uses 40-80% of the plants energy use, accounting for 15-20% of the plants operational expense.

- Aeration accounts for 4% of electricity consumed in the US.

- Municipal waste consumes over 30 terawatt-hours of electricity per year, costing roughly $2 Billion annually

- Wastewater treatment produces emissions on par with the Concrete industry.

- Aeration cannot provide process intelligence; plants rely on daily or more testing

VIVA™ MFC

The world's first Microbial Fuel Cell (MFC) platform that treats wastewater streams from high-strength industrial waste to low-strength municipal waste, and retrofits to nearly any existing system. VIVA’s modular system can easily retrofit into plants both small and large.

Process Intelligence

- VIVA™ MFC provides real-time treatment monitoring and can diagnose biological upsets and mechanical issues, down to an individual electrode. The plant operator can receive automatic alerts (although rare) and existing sensors such as pH, Nitrate, Solids, ammonia and ORT can augment the system’s intelligence.

High Energy Efficiency

- VIVA™ MFC reduces energy use by 85-90%, typically a reduction of 20% or more in plant operating expense.

Energy Recovery

- VIVA™ generates clean DC power in addition to energy-savings, providing a new source of renewable back-up energy for your facility.

Nutrient Recovery

- VIVA™ MFC reduces Nitrogen by 35-40% with no extra energy.

Aeration without Air

- VIVA™ performs aerobic treatment in an anaerobic environment. The microbes "breathe through electrical circuits" using our solid electrodes as part of their respiratory process.

Real Time Monitoring

- VIVA™ MFC can notify the operator if there is a biological or physical problem, right down to the exact circuit.

High Biological Stability

- VIVA™ systems are stable, even in plants with high-strength waste, frequent swings in pH, and effluent strength.

VIVA™ MFC vs. Aeration

| VIVA™ MFC to High-Efficiency Aeration | Existing High-Efficiency Aeration | VIVA™ MFC |

|---|---|---|

| Aeration Energy Use | 1770 MWh annually | 160 MWh annually |

| Electricity Cost | > $150K/year | < $10K/year |

| Greenhouse Gas Emissions | 1253 metric tons CO2 | .8 – 1.6 metric tons CO2 |

| CO2 Equivalents (miles driven, average passenger car) | 3,100,000 miles | 2,000 miles |

| DC Power Generation | $0 – no energy generation | 50+ MWh annually |

Want to Learn More About VIVA's Performance?

Tell us about your interest. Let's have a conversation.

Get in Touch